Our products

Maximising the return on your technology investment

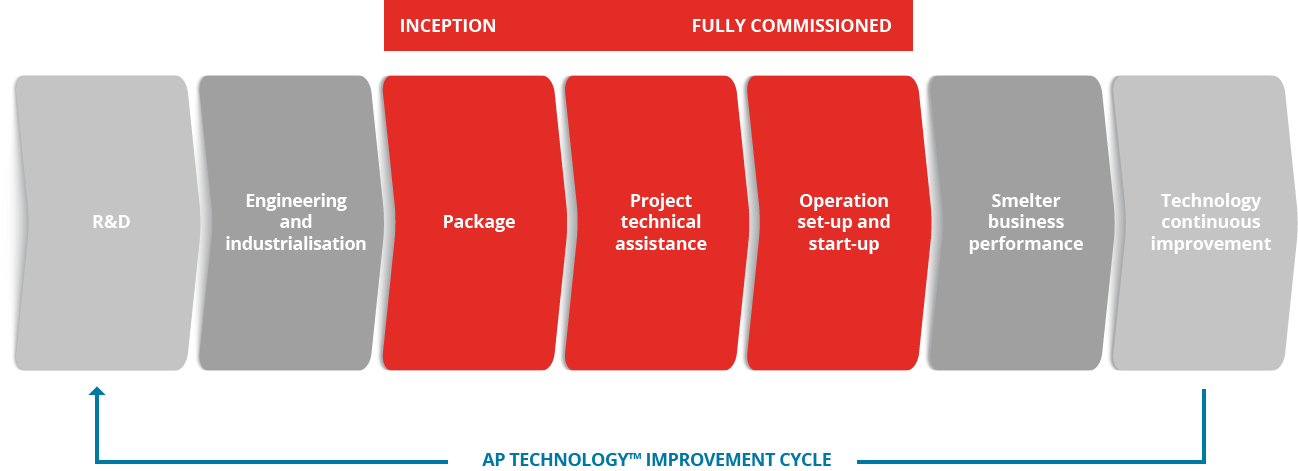

At Rio Tinto Aluminium, we’ve been operating smelters around the world for more than a century. We’ve spent the last 30-plus years developing and implementing our AP Technology™ solutions, at an average of one smelter project per year. This in-depth knowledge and experience allows you to maximise your project’s value and bankability using AP Technology™.

Smelter technology transfer:

the world reference

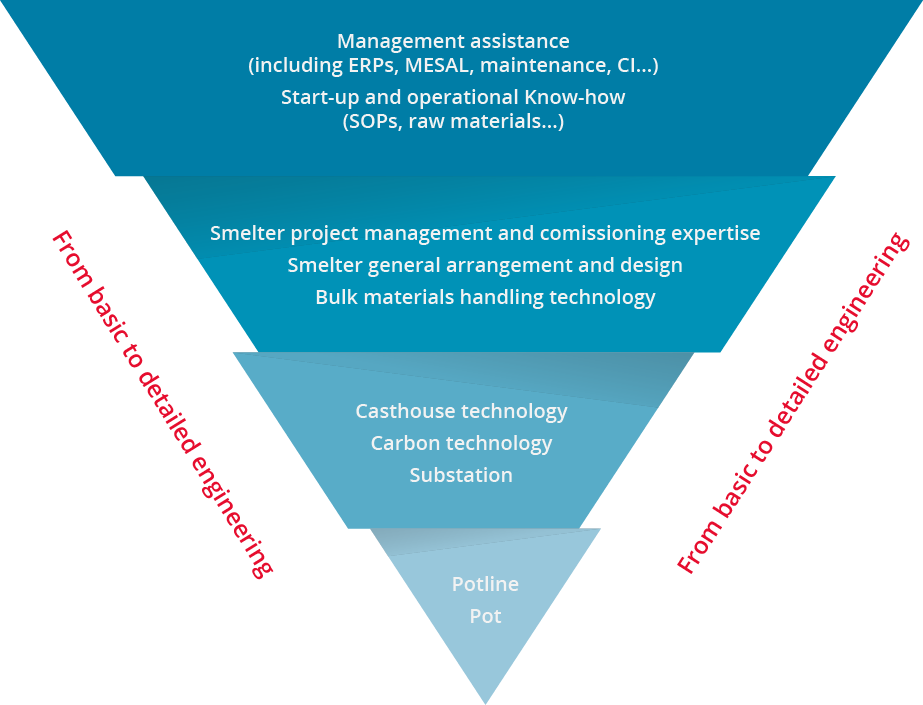

From pot design to global project execution and operational excellence, our AP Technology™ solutions are the industry benchmark for delivering optimal value.

Integration

Maximising the return on your technology investment

Over the decades, constant R&D and trials in our own plants have maintained our technological edge. We’ve learned that solutions integration is key to reaching the highest level of project and operational performance.

The AP Technology™ delivery integrates construction and operational requirements. It includes an optimised plant layout and encompasses all areas of the smelter. Our documentation package enables you to meet your project performance and reliability targets. It’s supported by AP Technology™ experts who work with your teams at all project stages, from feasibility studies to detailed engineering, construction, commissioning, Operations Readiness Planning (ORP), start-up and operations.

Greenfield or creeping projects

Our AP Technology™ teams support all sizes and types of projects. For both new and existing facilities, our methodologies and technologies maximise your project’s outcome and minimise its cost.

For creeping projects, we’ve developed a comprehensive approach to execute rapidly and keep risks under control. Many smelters around the world have benefited from this approach including several of our own.

Continuous improvement, superior value

Our dedicated R&D and industrialisation teams work together to continuously improve the AP Technology™ offer. From one project to the next, we build on the lessons learned and leverage our diverse industrialisation initiatives to drive breakthroughs and enhancements.

AP Technology™ solutions reduce both CAPEX and OPEX, minimising the full economic cost of your project. It optimises value right from the early basic engineering designs and concepts through to the detailed studies and construction works. We also ensure a smooth start-up with efficient support from our experts. The AP Technology™ package enables effective standardisation and change management.

Your partner at every step

We provide the necessary technical information, support and integrator experience to ensure your success at every phase of your project:

- Development

- Execution

- Commissioning, start-up and operations

Development

During this critical stage, the project scope, budget and implementation plan are defined and frozen. We support you by:

- Identifying the best available AP Technology™ solutions

- Developing a technical data list consistent with the project scope and objectives

- Preparing a pre-feasibility/feasibility package and a cost estimate

We work closely with you to finalise the project scope and plant layout. This allows the engineering firm to focus on detailed engineering, construction efficiency, strategic planning and the project execution plan.

With the project scope frozen and an approved technical data list and plant layout, we prepare and organise project specifications and drawings into packages. These packages are delivered according to milestones adapted to your planning requirements.

Execution

As with any sophisticated technology transfer, the support of experienced experts focused on assisting your project team and engineering firm is crucial.

The experts seconded to your project bring the unique combination of knowledge coupled with strong Rio Tinto Alcan back office support. They help the project and operations teams streamline execution and optimise preparation to ensure an efficient and successful start-up.

Commissioning, start-up and operations

With the operations teams now ready to take over from the project teams, this phase is essential for establishing the pace and performance of your smelter. Working on-site with your teams, our operations experts provide technical training and support including pertinent tools and methods.

Our Operations Readiness Plan (ORP) experts help you:

- Plan pre-operational tests

- Procure raw materials

- Conduct pre-start-up audits

- Create an efficient start-up organisation